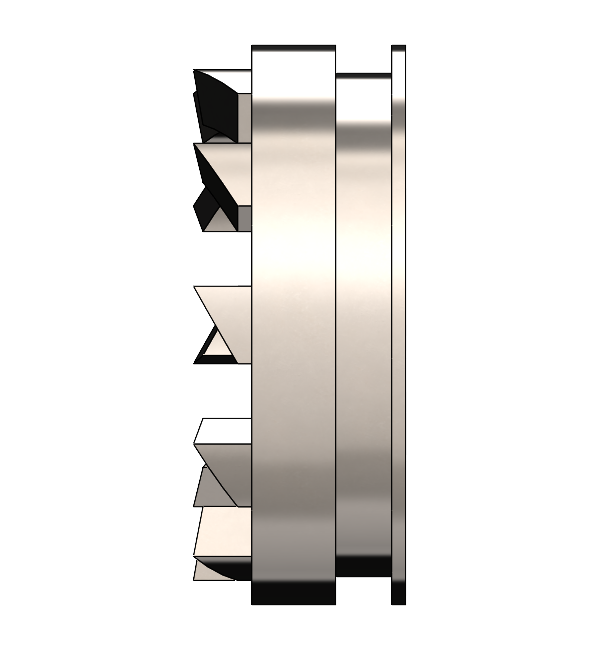

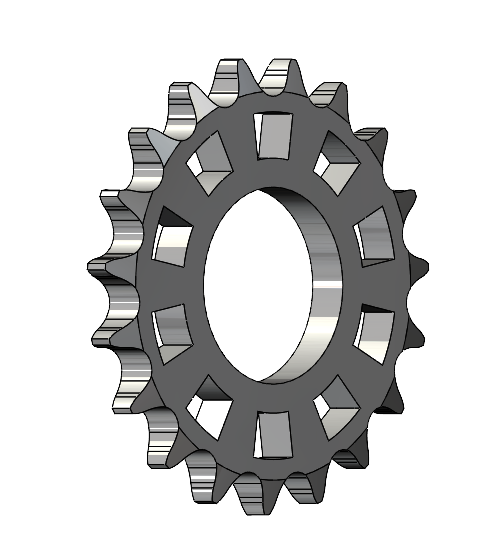

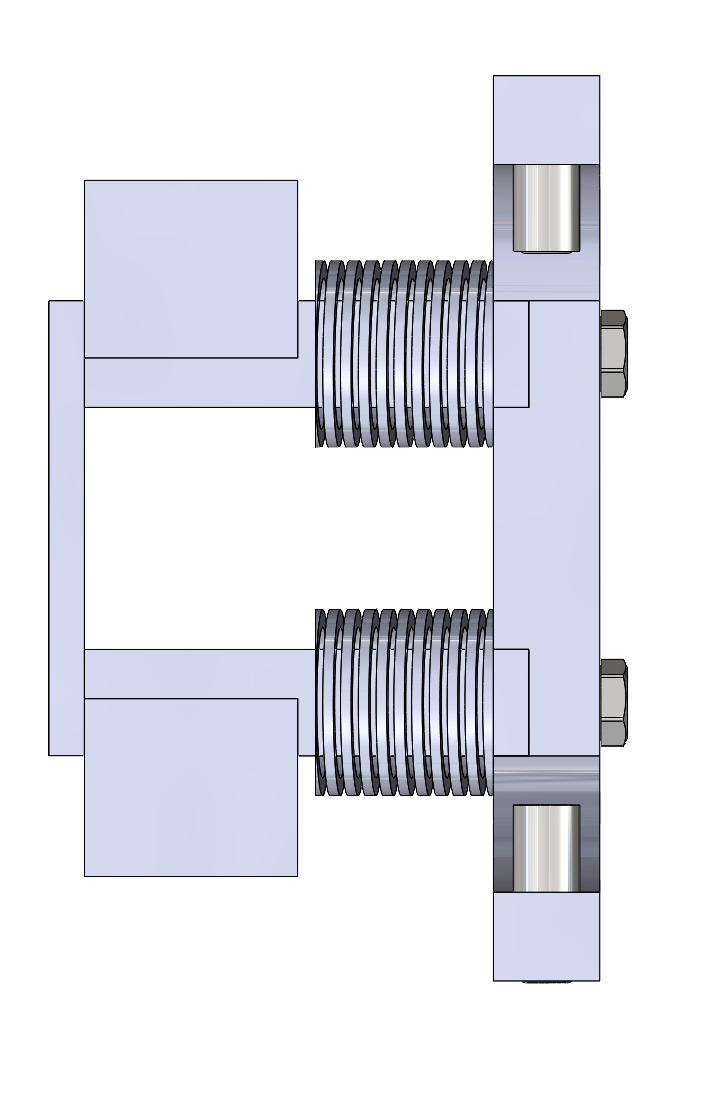

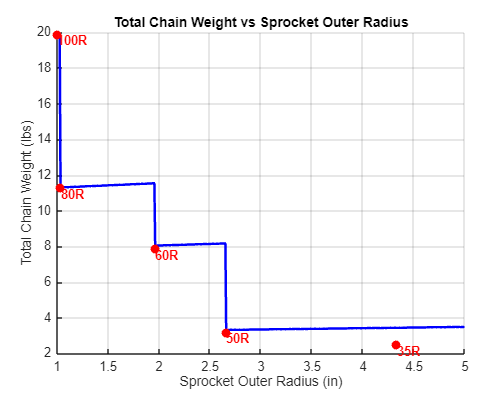

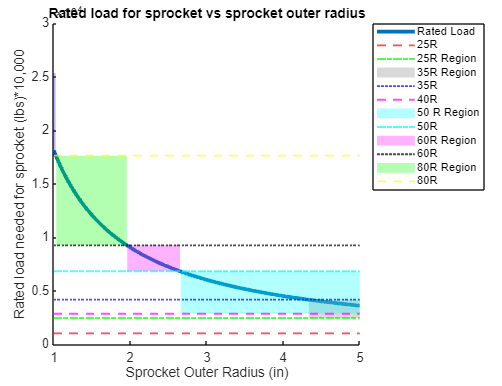

The sprocket component was determined through detailed MATLAB calculations to optimize our chain drive system. This component interfaces with the dog clutch to provide reliable power transmission when engaged. The sprocket design ensures optimal chain engagement and efficient power transfer to the front wheels.

- Optimized through MATLAB calculations

- Designed for seamless dog clutch engagement

- Custom tooth profile for optimal chain performance

- High-strength alloy steel construction